Introduction to Brass

Brass is a versatile alloy that has been valued by civilizations for centuries due to its unique combination of properties and aesthetic appeal. From ancient artifacts to modern industrial applications, brass continues to play a significant role in various aspects of human life. In this article, we will explore everything you need to know about brass, including its composition, properties, uses, and much more.

Join our: Whatsapp Group

What is Brass?

Brass is an alloy composed primarily of copper and zinc, with the proportions of each metal varying depending on the desired properties of the final product. It is renowned for its gold-like appearance and malleability, making it a popular choice for decorative items, musical instruments, and plumbing fixtures.

Elemental Information

- Copper (Cu):

- Atomic Number: 29

- Atomic Mass: 63.546 u

- Electron Configuration: [Ar] 3d¹⁰ 4s¹

- Zinc (Zn):

- Atomic Number: 30

- Atomic Mass: 65.38 u

- Electron Configuration: [Ar] 3d¹⁰ 4s²

- Symbol: The chemical symbol for brass is CuZn.

Chemical Properties

- Composition Range: Brass typically consists of 60-70% copper and 30-40% zinc, although these proportions may vary depending on the specific alloy and its intended application.

- Density: The density of brass alloys ranges from approximately 8.4 to 8.7 grams per cubic centimeter (g/cm³), depending on the specific composition.

- Melting Point: The melting point of brass varies depending on its composition, with typical ranges between 900°C to 940°C (1652°F to 1724°F).

- Corrosion Resistance: Brass exhibits good corrosion resistance, particularly in atmospheric and marine environments, due to the formation of a protective patina on its surface.

Click Here For Latest Scrap Metal Rates

- Malleability and Ductility: Brass alloys are generally malleable and ductile, allowing them to be easily shaped, formed, and fabricated into various products and components.

- Electrical Conductivity: Brass possesses moderate electrical conductivity, making it suitable for electrical and electronic applications where conductivity is required.

- Thermal Conductivity: Brass has good thermal conductivity, allowing it to efficiently transfer heat, which makes it useful in heat exchangers and other thermal applications.

- Alloying Elements: In addition to copper and zinc, brass alloys may contain small amounts of other elements such as lead (Pb), tin (Sn), aluminum (Al), or nickel (Ni), which can influence the alloy’s properties and characteristics.

Types of Brass

Brass alloys can be classified into several categories based on their composition and properties. Some common types of brass include:

Alpha Brass

- Composition: Contains less than 37% zinc.

- Properties: Good cold working properties, suitable for intricate designs and decorative applications.

Alpha-Beta Brass

- Composition: Contains 37-45% zinc.

- Properties: Offers a balance between strength and malleability, widely used in engineering applications such as fasteners and gears.

Beta Brass

- Composition: Contains more than 45% zinc.

- Properties: High strength and hardness, often used in manufacturing processes requiring durable components.

Properties and Uses

Brass possesses a diverse range of properties that make it suitable for various applications across different industries. Some key properties and uses include:

Properties:

- Malleability: Brass can be easily shaped and formed into intricate designs, making it ideal for decorative purposes.

- Conductivity: It is an excellent conductor of both heat and electricity, making it suitable for electrical connectors and heat exchangers.

- Aesthetic Appeal: The distinctive golden hue of brass lends an aesthetic appeal to architectural elements, musical instruments, and jewelry.

Must Read : Top 5 Most Common Types of Metals and Their Uses

Uses:

- Decorative Items: Brass is commonly used in the manufacture of ornaments, sculptures, and architectural accents due to its attractive appearance and ease of manipulation.

- Musical Instruments: Many musical instruments, such as trumpets, saxophones, and cymbals, are crafted from brass for their superior sound quality and resonance.

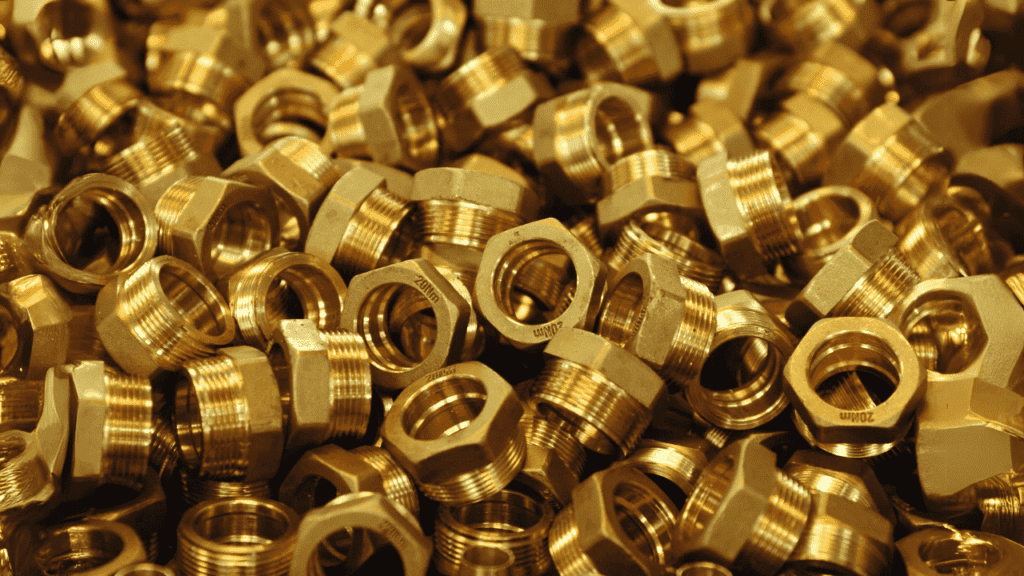

- Plumbing Fixtures: Brass fittings and valves are preferred in plumbing applications due to their corrosion resistance and durability.

- Industrial Machinery: Brass components are widely employed in machinery and equipment across various industries, thanks to their strength, machinability, and wear resistance.

- Automotive Parts: Brass alloys are utilized in automotive manufacturing for components like radiator cores, valves, and connectors due to their heat resistance and reliability.

Facts about Brass

- Ancient Origins: Brass has been used by civilizations dating back to at least 500 BCE, with evidence of its usage found in archaeological artifacts from ancient Mesopotamia and Egypt.

- Modern Production: Today, brass is produced through processes such as smelting, casting, and extrusion, with advanced techniques ensuring consistent quality and performance.

- Recyclability: Brass is highly recyclable, with scrap brass being melted down and reused to create new products, making it an environmentally sustainable material.

Definition and Meaning

Brass, in its most basic definition, refers to an alloy of copper and zinc, typically with copper as the predominant element. The term can also encompass alloys containing additional elements such as lead, tin, or aluminum, which are added to modify the alloy’s properties for specific applications. From a broader perspective, brass symbolizes versatility, durability, and aesthetic appeal in material science and engineering.

Also Read :LME : London Metal Exchange | Complete Details

Health, Environmental, and Side Effects

Health Implications:

- Copper Content: Brass may release small amounts of copper into food or beverages stored in brass containers, which can be harmful if ingested in excessive quantities.

- Allergic Reactions: Some individuals may experience allergic reactions to brass due to the presence of zinc or other alloying elements.

Environmental Impact:

- Recycling Benefits: The recycling of brass helps reduce the demand for virgin materials, conserves energy, and minimizes the environmental footprint associated with mining and extraction.

- Disposal Concerns: Improper disposal of brass products can contribute to metal pollution in soil and water sources, posing risks to ecosystems and human health.

Side Effects:

- Lead Content: Brass alloys containing lead pose health risks, especially if used in applications where lead exposure is a concern, such as drinking water systems or food processing equipment.

- Corrosion Products: Certain corrosion products of brass, such as copper salts, can be toxic to aquatic life if released into water bodies.

Benefits and Importance

Versatility:

- Wide Range of Applications: Brass finds applications in diverse industries ranging from construction and manufacturing to electronics and art, highlighting its versatility and adaptability.

- Customization Options: The ability to customize brass alloys by adjusting the proportions of copper, zinc, and other alloying elements allows manufacturers to tailor the material to specific performance requirements.

Related :Copper | Complete Details

Durability:

- Longevity: Brass products are known for their longevity and resistance to corrosion, ensuring reliable performance and minimal maintenance requirements.

- Mechanical Strength: Brass alloys exhibit excellent mechanical strength, making them suitable for demanding applications where durability is paramount.

Aesthetic Appeal:

- Elegant Appearance: The warm, golden color of brass adds a touch of elegance and sophistication to any environment, making it a preferred choice for decorative purposes.

- Artistic Expression: Artists and designers appreciate the aesthetic qualities of brass, using it as a medium to create intricate sculptures, jewelry, and architectural features.

Scrap and Recycling

Recycling Process:

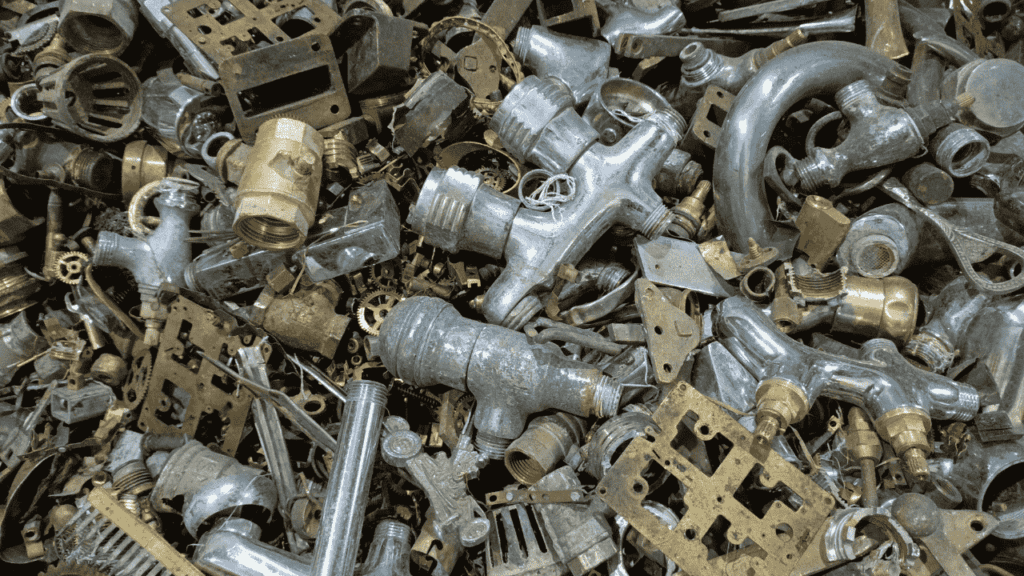

- Collection: Scrap brass is collected from various sources, including discarded products, manufacturing waste, and end-of-life components.

- Sorting: The collected scrap is sorted based on its composition and quality, separating pure brass from other materials and contaminants.

- Melting: The sorted brass scrap is melted down in furnaces, where it is purified and alloyed to achieve the desired composition.

- Casting: The molten brass is then cast into ingots or other forms for use in manufacturing new products.

Environmental Benefits:

- Resource Conservation: Recycling brass helps conserve finite natural resources by reducing the need for virgin materials extraction.

- Energy Savings: The energy required to recycle brass is significantly lower than that needed to produce it from raw materials, leading to reduced carbon emissions and environmental impact.

- Waste Reduction: Recycling brass minimizes the amount of metal waste sent to landfills, contributing to a more sustainable waste management system.

History and Future

Historical Significance:

- Ancient Origins: The use of brass dates back thousands of years, with early civilizations such as the Mesopotamians, Egyptians, and Greeks employing brass for decorative objects, tools, and weapons.

- Medieval Period: Brass continued to be valued during the Middle Ages, with advancements in metallurgy leading to the production of high-quality brass alloys for coins, armor, and religious artifacts.

Industrial Revolution:

- Mass Production: The Industrial Revolution brought about significant advancements in brass production techniques, such as the invention of the steam engine, which facilitated large-scale manufacturing processes and fueled the demand for brass components in machinery, transportation, and infrastructure.

- Technological Innovations: The 19th and 20th centuries witnessed the development of new brass alloys, improved manufacturing methods, and expanded applications in industries such as telecommunications, automotive engineering, and electronics.

Contemporary Applications:

- Modern Engineering: Brass remains a key material in modern engineering and manufacturing, with applications ranging from aerospace components to medical devices.

- Art and Design: Contemporary artists and designers continue to explore the creative possibilities of brass, incorporating it into avant-garde sculptures, installations, and functional art pieces.

Visit Our Prices Page For Latest Metals Rates

Future Trends:

- Sustainability: As environmental concerns grow, there is a growing emphasis on sustainable materials and manufacturing processes, positioning brass as a viable choice due to its recyclability and longevity.

- Innovation: Ongoing research and development efforts are focused on enhancing the performance of brass alloys through alloying, surface treatments, and additive manufacturing techniques, opening up new opportunities for its use in emerging technologies.

FAQs :

Q: What is brass made of?

A: Brass is primarily composed of copper and zinc, with varying proportions of each metal depending on the desired properties of the alloy.

Q: What are the main properties of brass?

A: Brass is known for its malleability, conductivity, and corrosion resistance. It has a warm, golden appearance and is easy to shape into intricate designs.

Q: What are the common uses of brass?

A: Brass is used in a wide range of applications, including decorative items, musical instruments, plumbing fixtures, industrial machinery, and automotive parts.

Q: Is brass environmentally friendly?

A: Yes, brass is highly recyclable, which helps conserve natural resources and reduce energy consumption compared to producing new brass from raw materials.

Join our: Whatsapp Group

Q: Are there any health concerns associated with brass?

A: Brass may release small amounts of copper into food or beverages stored in brass containers, but it is generally considered safe for most applications. However, brass alloys containing lead should be handled with caution.

Q: What is the history of brass?

A: Brass has been used by civilizations for thousands of years, with evidence of its usage found in ancient artifacts from Mesopotamia, Egypt, and Greece. It became more prominent during the Industrial Revolution with advancements in production techniques.

Q: What is the future of brass?

A: Brass continues to be an essential material in various industries, with ongoing research focused on enhancing its performance and sustainability through innovative technologies and processes.

Conclusion

In conclusion, brass stands as a timeless alloy that bridges the worlds of tradition and innovation. Its rich history, versatile properties, and wide-ranging applications underscore its enduring importance in various aspects of human civilization. From ancient artifacts to cutting-edge technologies, brass continues to inspire creativity, serve practical purposes, and contribute to a sustainable future.

Whether adorning architectural masterpieces, amplifying musical harmonies, or powering industrial machinery, brass remains a symbol of craftsmanship, durability, and aesthetic excellence. As we navigate the challenges and opportunities of the 21st century, the legacy of brass endures as a testament to human ingenuity and the enduring allure of this remarkable alloy.