Introduction to Aluminium

Aluminium, symbolized by Al and known for its lightweight and versatile properties, is a widely used metal with numerous industrial applications. From transportation to construction and consumer goods, aluminium plays a vital role in modern society. Its history dates back to the 19th century when it was first produced on an industrial scale. With its corrosion resistance, strength, and conductivity, aluminium is essential for various sectors, contributing to advancements and innovation worldwide.

Join our: Whatsapp Group

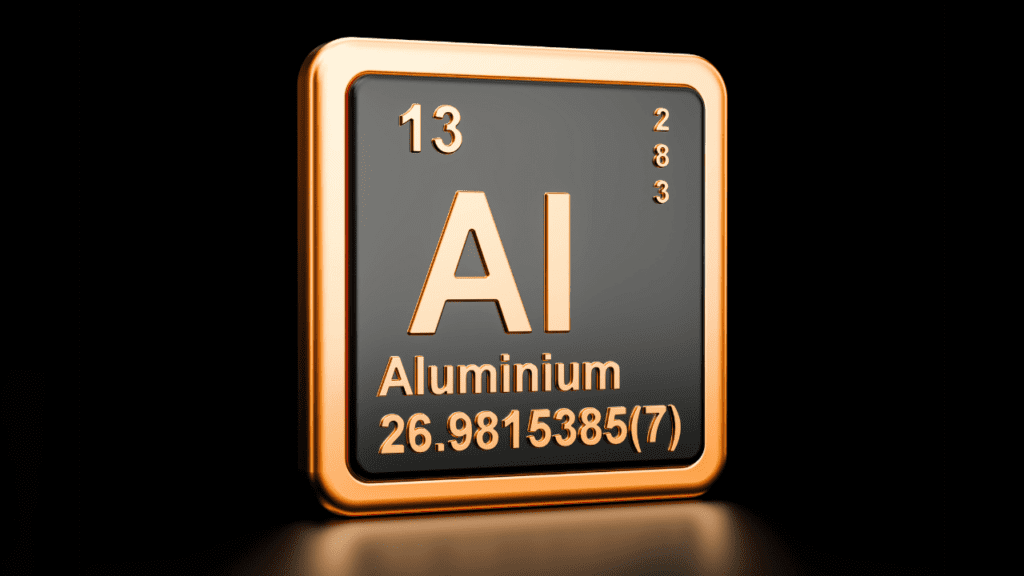

Element Information

Atomic Symbol: Al

Atomic Number: 13

Atomic Mass: 26.9815 u

Group: 13

Period: 3

Block: p

Electron Configuration: [Ne] 3s² 3p¹

Melting Point: 660.32°C (1220.58°F)

Boiling Point: 2467°C (4472.6°F)

Density: 2.70 grams per cubic centimetre

Chemical Properties

- Reactivity: Aluminium is a highly reactive metal, readily forming a protective oxide layer when exposed to air, which prevents further corrosion.

- Corrosion Resistance: The oxide layer on aluminium’s surface provides excellent corrosion resistance, making it suitable for outdoor applications.

- Thermal Conductivity: Aluminium is an excellent conductor of heat, making it valuable in heat transfer applications such as heat sinks and cooking utensils.

Click Here For Latest Scrap Metal Rates

- Electrical Conductivity: It also exhibits good electrical conductivity, although not as high as copper, making it useful in electrical transmission lines and wiring.

- Malleability and Ductility: Aluminium is highly malleable and ductile, allowing it to be easily formed into various shapes and drawn into wires.

- Alloying: Aluminium can be alloyed with other metals such as copper, zinc, magnesium, and silicon to enhance its properties for specific applications.

Types of Aluminium

- Pure Aluminium: Known for its high electrical conductivity and malleability, pure Aluminium finds applications in electrical transmission lines, packaging foils, and cooking utensils due to its non-toxic nature.

- Aluminium Alloys: Alloys of Aluminium offer a wide range of mechanical properties tailored to specific applications. For example, Aluminium alloys with copper (e.g., 2024 or 6061) are prized for their high strength-to-weight ratio, making them suitable for aircraft structures and high-performance bicycles.

- Anodized Aluminium: Anodizing Aluminium involves enhancing the natural oxide layer on its surface through an electrochemical process. This process not only improves corrosion resistance but also allows for decorative finishes and colouring, making it popular in architectural applications and consumer electronics.

Properties and Uses

- Lightweight: Aluminium’s low density, about one-third that of steel, makes it ideal for lightweight applications, such as in the automotive and aerospace industries, where reducing weight translates to fuel efficiency and improved performance.

- High Thermal Conductivity: Aluminium’s excellent thermal conductivity makes it an ideal choice for heat exchangers in HVAC systems, heat sinks in electronics, and cookware, ensuring even distribution of heat and efficient heat dissipation.

- Strength-to-Weight Ratio: Aluminium alloys offer exceptional strength-to-weight ratios, allowing for the construction of durable yet lightweight structures such as bridges, skyscrapers, and sporting equipment, where strength and durability are paramount.

Must Read : Top 5 Most Common Types of Metals and Their Uses

Interesting Facts About Aluminium

- Historical Rarity: In the 19th century, Aluminium was more valuable than gold or silver and was used sparingly for decorative purposes. The apex of its rarity is exemplified by Napoleon III of France, who reportedly reserved Aluminium dinnerware for his most honored guests.

- Abundance: Despite its historical rarity, Aluminium is the third most abundant element in the Earth’s crust, after oxygen and silicon, comprising approximately 8% of the Earth’s crust by weight. Its abundance ensures its widespread availability for various industrial and commercial applications.

- Recycling Success: Aluminium boasts one of the highest recycling rates of any engineering material. Approximately 75% of all Aluminium ever produced is still in use today, with recycling contributing significantly to resource conservation and energy savings.

Health, Environmental, and Side Effects

- Safety Concerns: While Aluminium is generally considered safe for use in food packaging and cookware, concerns persist regarding its potential health effects, particularly its association with neurodegenerative diseases like Alzheimer’s. However, scientific consensus on this matter remains inconclusive.

- Environmental Impact: The primary environmental concern associated with Aluminium is its high energy consumption during extraction and refining processes. Additionally, the extraction of bauxite, the primary source of Aluminium, can lead to habitat destruction and biodiversity loss if not managed sustainably.

- Recycling Benefits: Recycling Aluminium offers significant environmental benefits, including energy savings of up to 95% compared to primary production, reduced greenhouse gas emissions, and conservation of natural resources.

Also Read :LME : London Metal Exchange | Complete Details

Benefits and Importance

- Sustainability: Aluminium’s lightweight properties contribute to energy efficiency and reduce carbon emissions in transportation and construction. Its recyclability promotes a circular economy, reducing dependence on virgin resources and minimizing waste.

- Versatility: Aluminium’s versatility extends across diverse industries, from transportation and construction to packaging and electronics. Its ability to be alloyed with other metals further expands its utility and application range.

- Economic Contributions: The Aluminium industry generates significant economic value through job creation, technological innovation, and trade. Its widespread use stimulates economic growth and stability at local, national, and global levels.

Aluminium Scrap and Recycling

- Collection and Sorting: Aluminium scrap is collected from various sources, including discarded beverage cans, automotive parts, and building materials. Once collected, scrap Aluminium is sorted, cleaned, and processed to remove contaminants.

- Recycling Process: The recycling process begins with melting the scrap Aluminium in a furnace, where it is purified and cast into ingots or other shapes for reuse. This closed-loop recycling system ensures minimal energy consumption and environmental impact compared to primary Aluminium production.

- Environmental Benefits: Recycling Aluminium conserves energy, reduces greenhouse gas emissions, and minimizes the need for landfill space. Additionally, it helps preserve natural resources and ecosystems by reducing the demand for virgin Aluminium production.

Historical Background

- Discovery and Early Use: Aluminium was first isolated as an element by Sir Humphry Davy in 1808, though it remained rare and expensive until the late 19th century. Its commercial viability was realized with the invention of the Hall-Héroult process in 1886, which enabled large-scale production of Aluminium.

- Industrial Revolution: The availability of cheap Aluminium revolutionized industries such as transportation, construction, and packaging, leading to innovations in engineering, design, and manufacturing processes. Aluminium became a symbol of progress and modernity during the Industrial Revolution.

- Technological Advancements: Advances in Aluminium processing technologies, such as extrusion, casting, and fabrication, further expanded its applications and utility across diverse industries, propelling it to its status as one of the most widely used metals today.

Related :Copper | Complete Details

Future of Aluminium

- Technological Innovations: Ongoing research and development efforts are focused on improving Aluminium alloys, fabrication techniques, and surface treatments to meet evolving industry demands for lighter, stronger, and more sustainable materials.

- Sustainability Initiatives: The Aluminium industry is actively pursuing sustainability initiatives to reduce energy consumption, minimize environmental impact, and increase recycling rates. This includes investments in renewable energy, process efficiency improvements, and lifecycle assessments.

- Emerging Applications: Aluminium is poised to play a pivotal role in emerging technologies such as electric vehicles, renewable energy systems, and lightweight structural materials. Its unique combination of properties makes it indispensable for addressing global challenges related to climate change, urbanization, and resource scarcity.

Visit Our Prices Page For Latest Metals Rates

FAQs :

Q: What is aluminium?

A: Aluminium is a lightweight and versatile metal symbolized by Al, widely used in various industries for its unique properties and applications.

Q: What are the main properties of aluminium?

A: Aluminium is lightweight, corrosion-resistant, and has excellent thermal and electrical conductivity. It is also highly malleable and ductile.

Q: What are the common uses of aluminium?

A: Aluminium is used in transportation (cars, planes), construction (windows, doors), packaging (cans, foils), electronics (wires, heat sinks), and consumer goods (utensils, furniture).

Q: How is aluminium produced?

A: Aluminium is extracted from bauxite ore through the electrolytic process, where it is refined and processed into various forms for commercial use.

Join our: Whatsapp Group

Q: Is aluminium recyclable?

A: Yes, aluminium is highly recyclable, with approximately 75% of all aluminium ever produced still in use today. Recycling aluminium saves energy and resources.

Q: Are there any health concerns associated with aluminium?

A: While aluminium is generally safe, there are concerns about its potential health effects, particularly its association with neurodegenerative diseases like Alzheimer’s. However, scientific consensus on this matter remains inconclusive.

Q: What is the future of aluminium?

A: The future of aluminium lies in technological innovations, sustainability initiatives, and emerging applications such as electric vehicles and renewable energy systems. Aluminium’s versatility and sustainability make it indispensable for addressing global challenges.

Conclusion

Aluminium, with its remarkable properties and versatile applications, stands as a cornerstone of modern industry and innovation. From its historical rarity to its current status as one of the most widely used metals, aluminium has played a pivotal role in shaping human progress and technological advancement.

With its lightweight nature, corrosion resistance, and excellent conductivity, aluminium has found its way into countless products and industries, from transportation and construction to electronics and consumer goods. Its recyclability further enhances its appeal, contributing to resource conservation and environmental sustainability.

As we look to the future, aluminium remains poised to play a crucial role in addressing global challenges and driving technological innovations. From electric vehicles to renewable energy systems, aluminium’s unique combination of properties makes it indispensable for building a sustainable and prosperous future.

In conclusion, aluminium embodies the spirit of human ingenuity and resilience, symbolizing progress, innovation, and possibility. As we continue to harness its potential and push the boundaries of what is possible, aluminium will remain a steadfast companion, guiding us towards a brighter tomorrow.